Conveyance systems at

Amboss + Langbein

On the safe side

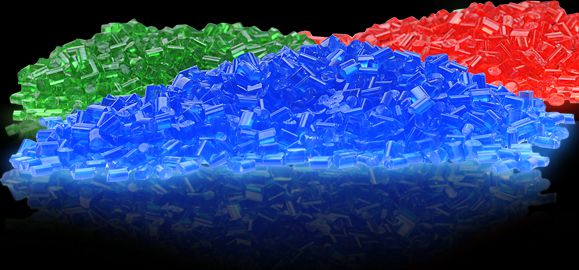

With the conveyance systems at Amboss+Langbein, hopper loaders are filled according to the “First in, First out” principle. Amboss+Langbein guarantees a transport capacity of c. 200 metres. The material throughput can reach up to 1.5 tonnes per hour. A dual bus cable design results in high operational reliability for the Amboss+Langbein hopper loaders. Our central system allows up to four vacuum circuits to be managed automatically, with capacity for up to

120 separators to connected to the system. An emergency motor design ensures trouble-free operation even in case

of vacuum generator failure.

The idling and material intake times of the hopper can be freely adjusted. The material can be selected for coded intake, making “improper” material intake due to incorrect coupling to the material station no longer possible. A visual and audible alarm ensures safety. The systems are equipped for self-optimizing material refill.

Conveyance systems

- Connected hopper loaders filled according to the “First in, First out” principle

- Expandable to a max. of 120 separators

- Supports up to 4 vacuum circuits

- Freely adjustable idling time at the hopper loader

- Freely adjustable materials intake time at the hopper loader

- Adjustable material selection for coded material intake; “improper” material intake due to

incorrect coupling at the material station no longer possible - Visual and audible alarm in the event of failure

- Equipped for self-optimizing material refill

- Automatic batch change

- Display of system state via Web browser at any workstation

- Display of delivery rate in hourly throughput for each loader via Web browser,

no special software necessary